1. Introduction

Piramal Glass is a leading moulded glass bottle manufacturer in India. The $330 million company has four manufacturing facilities globally – two in India, at Kosamba and Jambusar in Gujarat, two overseas, in Sri Lanka and the U.S. The four facilities (with a combined infrastructure of 12 furnaces and 60 production lines) with a capacity of 950 tonnes of glass per day. Piramal Glass is predominantly an exporter of specialised glass bottles for perfumes, beauty products and medical vials, with 65% exported to the U.S. and Europe. It is the world’s third-largest producer of nail polish bottles, with a 6% market share of global cosmetics and perfumery glass. In India, is one of the larger producers of bottles for the pharma industry.

This case study is based on the transformation of the Piramal Glass manufacturing plant in Kosamba, the company’s oldest and the largest facility, and how this brownfield factory accelerated digitization during the Covid-19 pandemic. Acquired in 1984, it began with the manufacturing of vials, liquor bottles and food jars, and today makes high-value perfume and medical glass products.

2. Transformation Goal

The company began its digitization journey in 2014, to ensure that the entire production line was connected with sensors, the data collected and analysed for efficiency, quality and safety. Samit Datta, the company’s Global Chief Supply Chain & Technology Officer, led this initiative.

3. Methodology

- For its digital transformation, Piramal Glass has used a judicious mix of products and services from established players and start-ups.

- Between 2007 and early 2014, a number of digital processes were introduced, leveraging its existing IT assets and SAP. to enhance productivity. The focus was to enhance the productivity of existing factory assets, human resource management, quality, and safety.

- By 2014, the company initiated transitioning from on-site servers to cloud-based tech. The management then brought the employees into the transition process, asking for ideas based on their experiences. The ideas began to pour in by the thousands. By 2015, it became clear that digitization was enthusiastically embraced, and Piramal Glass described it as part of its manufacturing DNA.

- Piramal Glass was growing rapidly, tripling from Rs 6.5 billion in 2006 to Rs 22 billion in 2016 – all on 2007 technology. and a year later in 2017, undertook comprehensive revamping of IT infrastructure both hardware and software across all facilities in India, Sri Lanka and the United States. This included – revamping the network elements, upgrading servers at the data centres and endpoint devices across the company.

- In 2016, Piramal Glass undertook an extensive business process reengineering study to map the relevance of existing IT applications to the business processes and realities. As an outcome of this study, in the ensuing one year, the company upgraded SAP to the latest version (SAP S/4 HANA) and shifted to Microsoft Azure – with its enhanced capabilities.

- In 2016, Piramal Glass also appointed a Chief Digital Officer. It then hired a consultant – Wipro to develop a digital strategy and a three-year implementation roadmap that closely aligned with the overall business strategy. A digital integration was begun, for a smart manufacturing process, a connected supply chain, and externally, for a customer-centric digitization.

- A Pune-based start-up, Websym[1], was hired to implement an IoT pilot on two manufacturing lines. At each stage, the digital process or product was evaluated by efficacy, contextual fit, impact on employees and customers, and cost-benefit analysis. It was hugely successful, and cost efficient; Websym charged just over $ 5000.

- In six months, by the end of 2017, the digitization process[2] was implemented in all the four facilities, at a cost that was 70% lower than if a large MNC had been hired for it. Over 4,000 sensors are now connected to each other, generating millions of data points and enabling the goal of productivity, quality and safety. The company’s efforts were showcased by Microsoft CEO Satya Nadella at the ‘Future Decoded 2020’ forum to India’s leading CEOs, as a model use case for Microsoft Azure.

- A major cost for the company, are its 12 energy-guzzling furnaces. Half of these are at the Kosamba plant. Existing solutions came from MNCs, mostly one-key-fits-all solutions. Piramal Glass wanted a customised solution, and turned once again to start-ups – this time to a Ahemdabad based company called Ecolibrium Energy[3]. Over 800 meters with sensors were installed[4] in the Kosamba factory, and the data mined therein opened up opportunities for energy savings and reduction of carbon footprint.

- An on-going effort, begun in 2019, is the creation of a digital twin for all the furnaces, with Piramal Glass’ in-house engineers. This will provide a simulation platform for predictive performance of assets.

4. Success Stories

Pre-COVID-19

i. Factory Floor

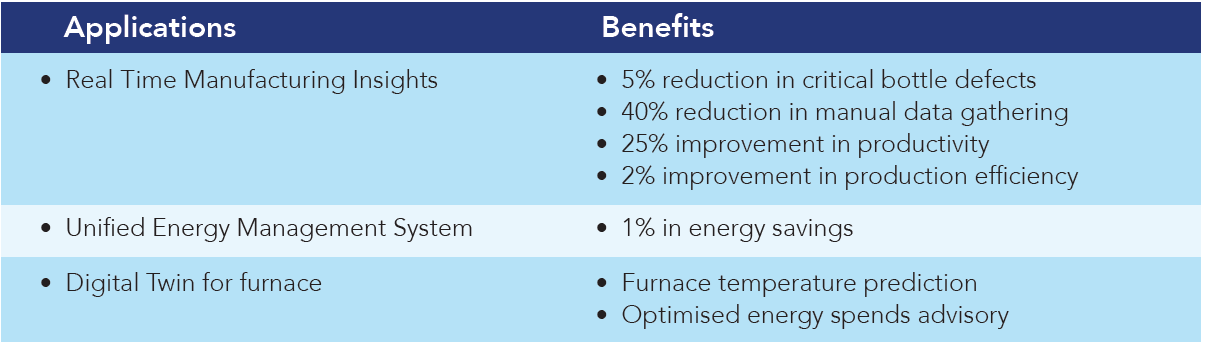

- Some of the digital innovations on the factory floor and the benefits accrued are tabulated below: –

Table 1: Value Creation

ii. Connected Supply Chain.

- Piramal Glass ships 600 containers of its product to over 80 countries every month. That’s 250 million bottles being sent out globally every month. The tracking system was manual. In 2018, Piramal Glass switched to geo-tagging and satellites for tracking its shipments in real-time over surface (trucks) and ocean (container ships). A German company (Ocean Insights[5]), provided tracking system for shipped containers at sea that also included a seamless platform for secure e-sharing of various documents pertaining to the shipment with customs departments of various countries. It coordinates multiple data feeds from customs databases, GPS, shipping line databases.

- For tracking its container trailers Piramal Glass successfully developed, in-house a smart- phone GPS based tracking system. But this could not be replicated to the Indian trucking system as many truck-drivers did not have smart phones. So, its engineers adapted to use Base Transceiver Station (BTS) technology – a relatively lower technology compared to GPS based tracking. BTS works with GSM and CDMA mobile handsets – a feature common to Indian truck drivers. Piramal Glass once again tapped a local Indian Start Up – Freight Tiger[6] for this innovative solution.

iii. Human Resources.

- A gamified crowd-sourcing platform called Innohub was developed in house to encourage employees to ideate on innovations. It has generated over 16,000 ideas, many of which have been implemented. Innohub was also built on a platform provided by an Indian start up – WorXogo[7]. This not only resulted in democratisation of innovation, but also accelerated small ticket capex projects that resulted in monetary savings.

- A multilingual, cloud-based e-learning platform was developed in-house for on-demand training to employees, with over 40 courses that include technically intensive sessions critical to factory floor operations.

COVID-19

Since 2017, Piramal Glass has developed, a strong digital innovation ecosystem that has helped create connected infrastructure and supply chains. This early impetus to stay abreast with the digital revolution has progressively built resilience into their operations. In Mar 2020, as the country went into nation-wide lockdown due to the COVID-19 pandemic, the company that otherwise would have required to shut down, was able to operate remotely, maintaining business continuity. In April when the lockdown was lifted for essential services, Piramal Glass’ Indian factories resumed normal operations within a week, with 30% of the workforce, as permitted by the government.

1. Regulatory Compliance.

- Compliance to COVID-19 protocols for workers was mandatory and required rapid innovation. Pre- Covid, at the factory gate company workers used finger-print biometrics to enter the factory premises. That became impossible and the company switched to a computer-vision based non-contact biometrics with which workers could enter and login attendance. Piramal sourced this domestically from a start-up called Smart Infocomm implemented a facial recognition & IR-based system called WebSmart that registered contactless attendance and logged body temperature of individuals prior their entry into the factory premises even with their faces partially covered with mask.

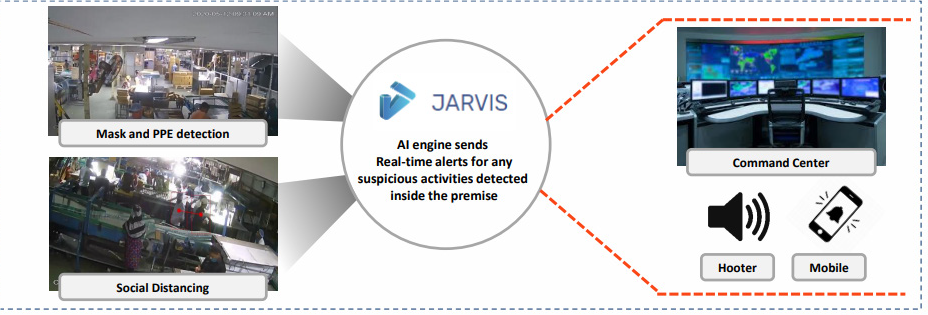

- Similarly, the companies’ engineers adapted the existing CCTV network with another computer-vision based algorithm which was used to create alerts for those factory-floor personnel who violated mask and social distancing norms. Alerts were generated and logged automatically that helped in flagging habitual offenders and increasing regulatory compliance.

Figure 1: Video Analytics for COVID-19 Norms Compliance

2. Virtual Assist.

- Virtual Reality (VR)-based technology was used to commission the upgraded a furnace to increase its capacity by 50%. Under normal circumstances it would have taken 10 experts from Europe to be onsite. The augmented reality technology comprised of smart glasses which were procured locally. It took the same time, but it saved costs and boosted in-house engineering capabilities.

- Secondly customers who would normally be sent physical samples of glass, were able to undertake virtual inspection of products using Virtual Reality. Piramal engineers indigenously developed a light box with high resolution cameras which enhanced virtual inspection of glass quality in real-time. Personnel from Piramal and its customers used virtual assist technology (voice and visual) to collaborate for dimensions and visual defect detection.

- Thirdly, the virtual reality technology allowed a virtual plant walkthrough for customers.

5. Future Plans

Since 2014, Piramal Glass has generated billions of data points, by leveraging the power of IIoT. This will now be used to create new analytical models to generate deeper insights into various operations for creating a truly end-to-end digital enterprise.

In July 2020, the company hired a leading consultant to scale-up the digitisation journey Digital 2.0 will focus on Artificial Intelligence and machine learning techniques to increase business and enhance work-force digital capabilities.

6. Key Findings

Brownfield operations can digitally transform by building on existing IT infrastructure by implementing a mix of physical and digital innovations. Adoption of IoT and cloud-based digital innovations, using start-ups and blending indigenous and foreign technologies can help older facilities conserve capital and build agility and resilience in their operations. They must seize the opportunities presented by the ongoing pandemic crisis to rethink their business models, set ambitious goals and trust employees with ideation and innovation.

- Building on existing IT Infrastructure: A robust IT infrastructure is a stepping-stone for digital transformation. Factories must upgrade IT assets to a level that can facilitate adoption of IoT and cloud-based technologies.

- Using Start-Ups: Start-ups must be considered for digitisation and digitalisation efforts as they offer high-customisation and frugality. This approach reduces upskilling demands internally within the organisation and also aids in capital conservation.

- Blending technology: There is no silver bullet for digital transformation and organisations must deep-dive into the problem statement at hand and available technologies. The choice of technology must be based on its ability to address a problem statement and create value. Technologies chosen must cater for accuracy, reliability, interoperability, agility and most importantly scalability.

- Seizing crisis: The ongoing pandemic has enforced challenges on traditional business models. Companies like Piramal Glass that have adopted digital as a strategic tool for business operations are reaping the benefits of accelerated transformation during the pandemic. Others must seize this opportunity to rethink their business models and make them future-ready.

- Developing inhouse culture for ideation: Core manufacturing knowledge is crucial for customisation of digital tools that can be deployed and accepted on the factory floor. Involving inhouse workforce in ideation and problem solving has not only helped Piramal build an innovation culture across the workforce, but also has resulted in development of solutions that work and are accepted at the grassroot of the factory.

- Setting ambitious goals: The need for change must be top-driven and must seep into the organisation vertically and horizontally. Putting an ambitious goal in front has helped Piramal Glass to put digital transformation at the forefront of their entire operations and culminate in global recognition in the coming years – perhaps as the latest Indian entrant into the prestigious World Economic Forum recognised Light House network.

Commander Amrut Godbole is Fellow, Indian Navy Studies Programme at Gateway House.

Sagnik Chakraborty is Researcher, Cybersecurity Studies Programme at Gateway House.

Manjeet Kripalani is Executive Director and co-founder at Gateway House.

This study was conducted by Gateway House, in partnership with India EXIM Bank. Read the full study here.

For interview requests with the author, or for permission to republish, please contact outreach@gatewayhouse.in.

Disclaimer: The contents of the paper are personal views of the author and do not reflect the official position of the Indian Navy or Government of India.

© Copyright 2021 Gateway House: Indian Council on Global Relations. All rights reserved. Any unauthorized copying or reproduction is strictly prohibited.

References:

[1] “Solutions to Drive Operational Excellence!” Websym. Accessed February 10, 2021.

[2] This digitization effort led to the implementation of Real Time Manufacturing Insights (RTMI) platform – the flagship transformation programme at Piramal Glass.

[3] “Industrial Equipment Predictive Maintenance Software – Ecolibrium Energy.” Industrial Equipment Predictive Maintenance Software@Ecolibrium Energy. Accessed February 10, 2021.

[4] These sensors feed into another inhouse platform – Unified Energy Management System (UEMS) that is used to build insights into consumption of utilities like electricity, gas, air and water.

[5] “About Us.” Ocean Insights, January 19, 2021.

[6] “Logistics That Empowers.” Freight Tiger. Accessed February 10, 2021.

[7] “Drive Sales Behaviors.” worxogo. Accessed February 10, 2021