Courtesy: World Economic Forum

Courtesy: World Economic Forum

In March 2021, the World Economic Forum (WEF) announced the addition of 15 manufacturing facilities to the prestigious Global Lighthouse Network. Two Indian companies were on the list – the Tata Steel facility in Jamshedpur, and the ReNew Power facility in Hubli. This is twice the number of Indian companies on the list last year. Many more facilities will likely be added to the WEF list, as several prepare to graduate their manufacturing businesses to keep up with Industry 4.0.

Courtesy: Gateway House

Courtesy: Gateway House

Digital manufacturing is the next wave of business globalisation, which, post-pandemic is not just blind automation to save costs but the smart use of digital tools to modernise industry and create good quality jobs. Digital manufacturing is the next leap for India’s tech leadership - the first being the software outsourcing movement in the 1990s. This time around, government incentives are aligning with industry interests. It offers India a chance to reposition itself globally, and play a leadership role.

Courtesy: Shutterstock

Courtesy: Shutterstock

Tata Steel is one of the few global companies on the prestigious Global Lighthouse Network for its advanced digital manufacturing systems - and it was the first Indian company on the list. The vision of a digitally integrated manufacturing facility was introduced when the Tata Steel Kalinganagar plant (TSK) was conceptualized in 2006. The subsequent implementation and continuous upgrade of the facility has made it a global benchmark. This case study on TSK's journey can guide other companies to overcome challenges in upgrading systems, using artificial intelligence and big data analytics to increase efficiency and drive innovation.

Courtesy: Shutterstock

Courtesy: Shutterstock

COVID-19 has forced India and its manufacturers to quickly step up their adoption of digital manufacturing processes. There are four elements of this ecosystem already in place – the digital infrastructure, government schemes, academic learning, and a burst of start-ups. This, supported by key policy decisions by the Indian government, will propel Indian manufacturing to higher levels of efficiency, productivity, and competitiveness.

Courtesy: Shutterstock

Courtesy: Shutterstock

The world is experiencing two simultaneous transformations: a decoupling from China and the building of an alternate supply chain, and the creation of new, cutting-edge industrial process called digital manufacturing. It is part of the larger wave of Industry 4.0, an integration of industrial processes with the Internet of Things. India already has some of the key elements in place, and some successes to build on.

Courtesy: Gateway House

Courtesy: Gateway House

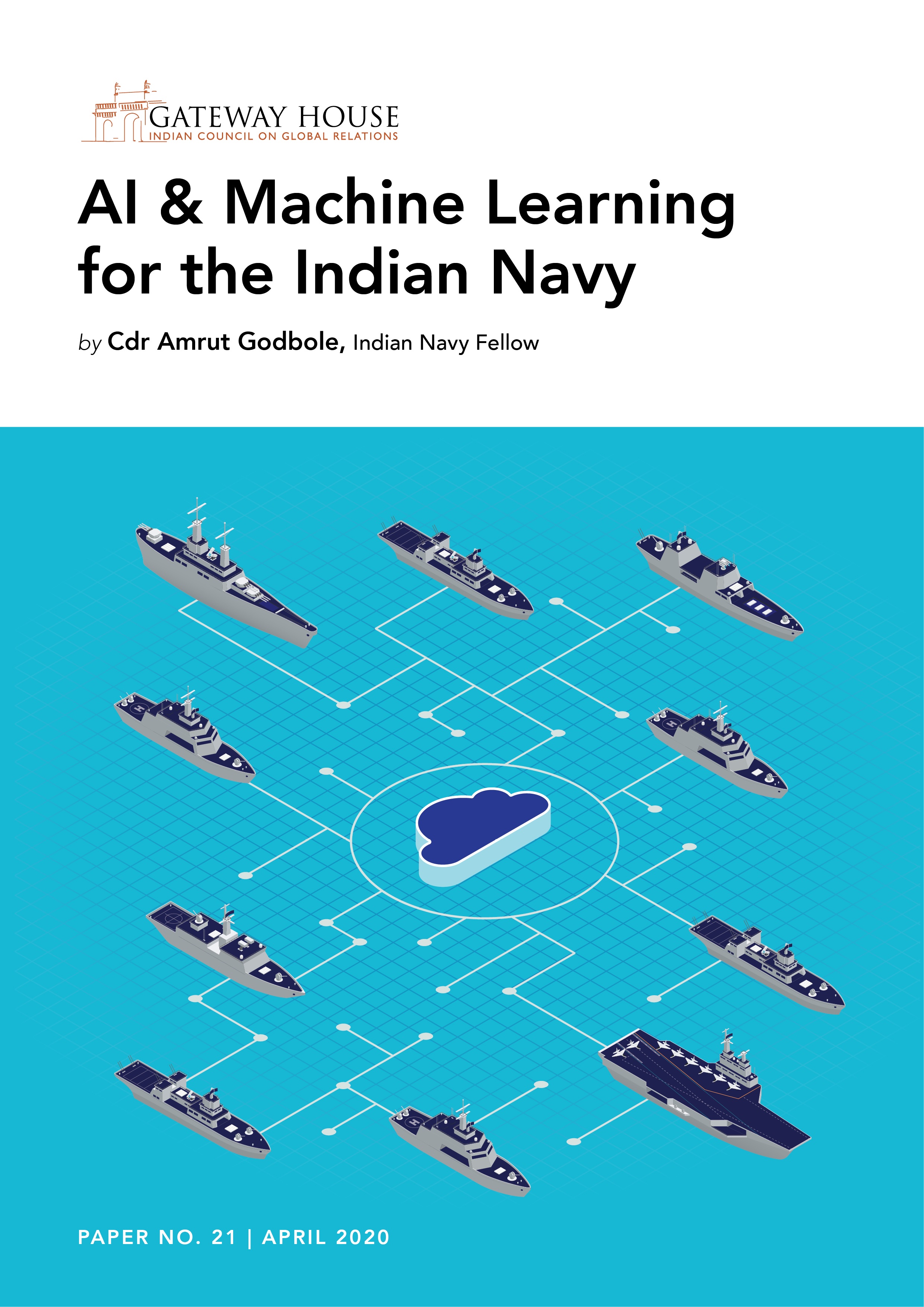

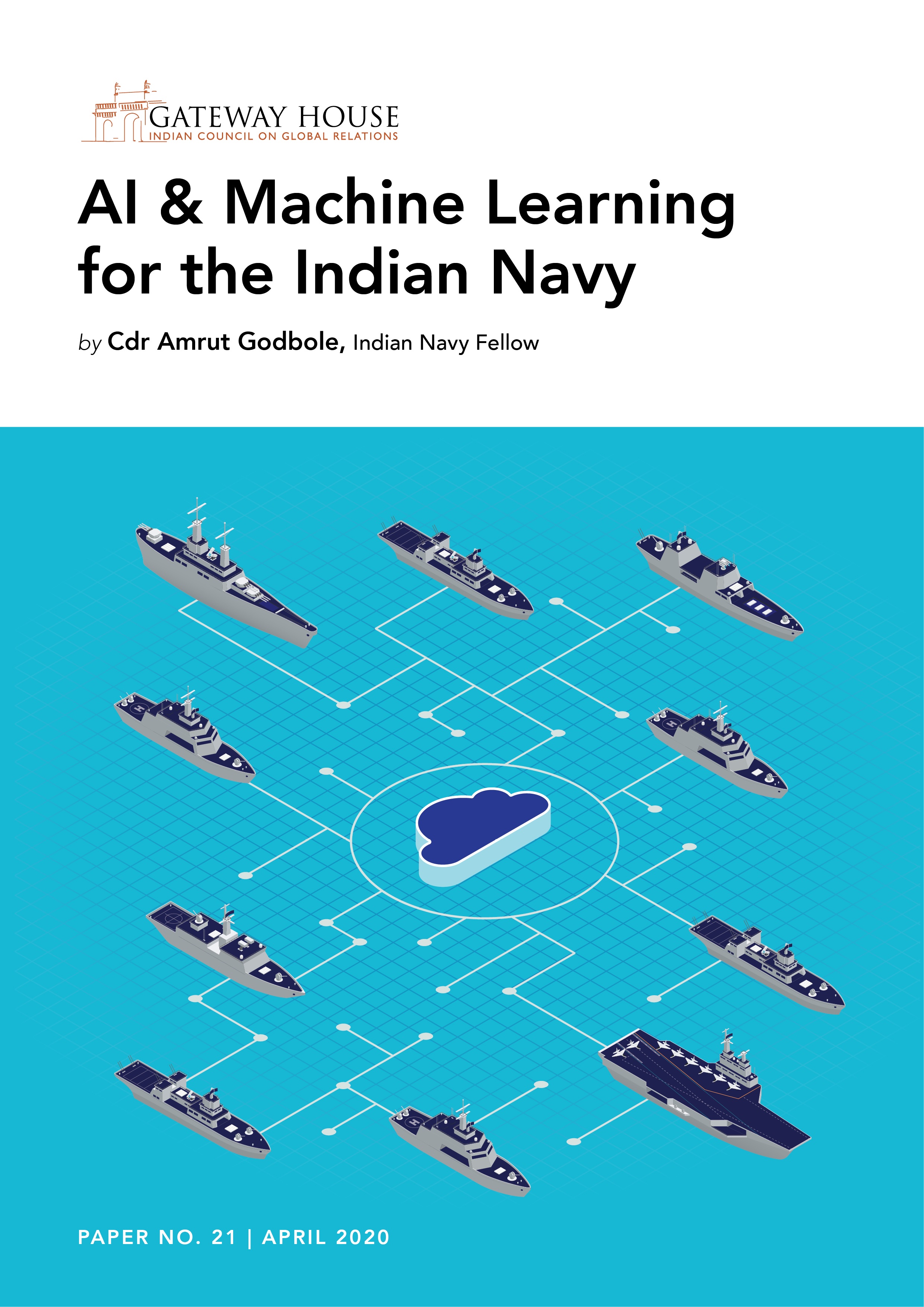

The Indian Navy needs to develop and assimilate new Artificial Intelligence (AI) technologies that are being used by the Indian military and industry. The Navy's goals of transforming into a 200-ship force and maintaining optimal combat capability, are being put to test by diminishing capital and manpower shortages. It needs to leverage the benefits of AI and Machine Learning (ML) to improve organisational efficiencies at various levels. This paper focuses on four Use Cases, viz., Inventory Management, Training, Prescriptive Maintenance, and Security & Surveillance, for implementation in the Indian Navy.

Courtesy: Pixabay

Courtesy: Pixabay

The post-COVID19 environment may entail austerity measures for the armed forces. India’s most technology-savvy force, the Indian Navy, can lead a transformation by accelerating Artificial Intelligence applications, and keeping budgets tight through collaborations with industry.

Courtesy: Shutterstock

Courtesy: Shutterstock

Indigenous development of key Information Communication Technology (ICT) infrastructure is critical to scaling up the use of Artificial Intelligence (AI) within the armed forces. Home-grown cloud technology, like National Cloud Meghraj, can help in this transformation while also meeting India’s cyber-physical security demands for data exchange and data localisation

Courtesy: Shutterstock

Courtesy: Shutterstock

The pandemic has highlighted the positive role of 3D-printing technology. Identifying this potential, and seeking to insert India into the new global value chains, the Ministry of Electronics, IT & Technology has announced a National Strategy for Additive Manufacturing. It will address the lacunae in the country's additive manufacturing ecosystem, including physical hardware like printers, software, materials and service providers.

Courtesy: Shutterstock

Courtesy: Shutterstock

Oil prices, arms exports and conflict are inter related especially when it comes to the U.S. Its arms industry grows when high prices and conflicts coincide. This has kept West Asia on a perennial geopolitical boil. This infographic charts the highs and lows of U.S. arms sales, especially in the light of conflicts centred around West Asia